|

RIZHAO LONGNUO TRADE CO.,LTD

|

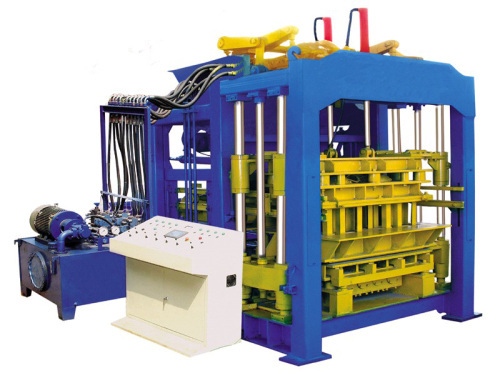

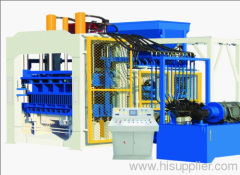

QT9-15 automatic brick making machine

| Price: | 64620.0~69600.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

QT9-15 Type Block Machine

1.electric and hydraulic system

2.synchronous vibration

3.The unique forcing charge system

QT9-15 automatic concrete brick machine

Brief introduction

1.It is controlled by PLC.person and machine have a conversation with computer.fault diagnosis system andl long-distance controlling is easy to study.

2.Electric system and hydraulic system work together with the machine.according to different material.,we can change the libration way and achieve low frequency in feeding material,high frequency making.the height of product on the same pallet has small erro and assure the consistency.

Main parameter:

1.overall dimension:7520*2220*2960mm

2.raterd pressure:21MPa

3. main vibration form:platform vibration

4.vibration frequency:2800-4500(r/min

5.pallet size :1350*720mm

6.molding cycle:15~25s

7.overal power:40.58kw

8.Raw material:crushed stone,sand,cement, dustand coal ,fly ash,

cinder,slag, gangue,gravel, perlite, and other industrial

wastes.

9.Applied products:concerte blocks.solid/hollow/cellular masonry

products,paving stones with or without face mix, garden

and landscaping products, slabs,edgers, kerbstones,

grass blocks, slope blocks, interlocking blocks,etc.

10.Applied fields:widely used in buildings,road pavers, squares, gardens, landscaping, city

constructions ,etc

Productivity

Item | Specification Size(mm) | Qty/Molding | Cycle Molding | Per hour |

Hollow brick | 390*190*190 | 9pcs | 20~25s | 1296~1620pcs |

Porous block | 240*115*90 | 25pcs | 15~20s | 4500~6000pcs |

Standard brick | 240*115*53 | 50pcs | 15~17s | 10500~12000pcs |

samples

Contact person: Carol

Contact person: Carol

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Automatic Brick Making Machines

Automatic Brick Making Machinery

Brick Making Machine

Cement Brick Making Machine

Concrete Brick Making Machine

Clay Brick Making Machine

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35